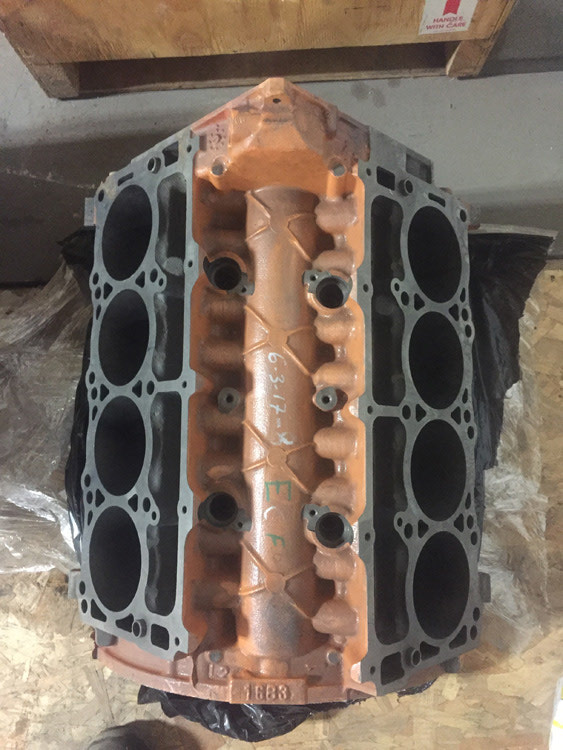

50cc Welding Cast Iron Engine Block Vogue 50 With 39.94mm Bore Diameter

For some cast irons you may only want to weld an inch or less and let cool 1 minute between passes. If the rod is not penetrating the cast iron, check the ground, amperage, and machine settings. After completing the cast iron weld, be sure to allow the part to cool naturally to avoid re-cracking.

50cc Welding Cast Iron Engine Block Vogue 50 With 39.94mm Bore Diameter

Features Engine Block and Head Repair A cracked cylinder head or engine block may or may not be bad news depending on the size and location of the crack (s), the value of the casting and what it will take to fix the crack (s) versus what it would cost you to replace the casting. Read what your options are in this Larry Carley feature.

Engine Block Repair Hot Rod Network

Syncrowave 210 TIG/Stick Welder The Syncrowave 351 shown at work here is a great unit from Miller's past, and shows just how robust Miller gear is, but if you're up for a job like this, you'll want.

50cc Welding Cast Iron Engine Block Vogue 50 With 39.94mm Bore Diameter

#1 · Jan 7, 2005 I have a cast iron engine block. The bolt holes that connect the tranmission to the block were broken off in an accident. The cyliders are fine. Is it possible to repair the bolt holes by building the area up around them and redrilling them. Of the six bolt holes 2 are broken (pic attached).

Diesel Cast Iron Engine Block Welding YouTube

When welding, cast irons do not stretch or deform when heated. Rather the metal can crack when exposed to heat and then cooling, which makes the entire welding process a challenge. Cast Iron Will Crack If Stressed or Elongated 1% to 2% Cast Iron Melting Point

50cc Welding Cast Iron Engine Block Vogue 50 With 39.94mm Bore Diameter

Andy Weyenberg Aftermarket and Performance Manager, Miller Electric Mfg. LLC From engine block repairs to fixing cracked cylinder heads, following key best practices can help overcome welding challenges. Repair aluminum, cast iron, steel and magnesium

Cast Iron Engine Welding Repair

So how do we weld cast iron? Repairing a cracked engine block is a much cheaper alternative than replacing it. Most welding done on cast iron is to repair cracks. It is good practice to find the ends of the crack and drill a small hole to prevent further crack propagation. Ensure drilling of these holes is done carefully.

Auto Welding Service Cast Iron Steel Welding Service

Engine Block Repair Your Cast Iron or Cast Aluminum Engine Block can be restored. Save your valuable serial numbers. We repair cracked or eroded Deck Surfaces, Internal and External Freeze Cracks, Main Web Cracks and Oil Galley Cracks. We also repair Impact Damage such as Block Holes and Pan Rail Damage.

Engine Block Repair Hot Rod Network

Drill holes at the end of any cracks to stop propagation Note : Please observe all AWS Safety & Health Guidelines when using Muggy Weld products. Weld a cast iron engine block with 77 electrode. A 2004 Jeep Wrangler motor block is welded with a mild steel patch and a Lincoln welder.

CAST IRON WELDING REPAIR (Bessemer Engine) YouTube

BLOCK PREPARATION A complete visual inspection of the block is performed. Repairs will be made to minor casting defects, removal of broken bolts are performed as well as repair and tapping of threads.

50cc Welding Cast Iron Engine Block Vogue 50 With 39.94mm Bore Diameter

If you are repairing a crack on the cast iron part like an engine block, drill two holes at both ends of the crack to prevent the crack from spreading any further as you weld. Welding temperature will cause local expansion and contraction, as we discussed earlier, and since cast iron is very brittle, the crack will propagate unless you drill.

Make The Case Iron vs. Aluminum Engine BlocksPerformance Racing Industry

If the part is on an engine, it may be possible to run it for a few minutes to obtain this temperature. Never heat the casting so hot that you cannot place your bare hand on it. Make short, approximately 1" long welds. Peening after welding is important with this technique. Allow the weld and the casting to cool.

Stick Welding Cast Iron Your go to guide Welding Mania

When finished welding the engine block, always allow the part to slowly cool naturally to avoid recracking. Note : Please observe all AWS Safety & Health Guidelines when using Muggy Weld products. This diesel cast iron engine had a large hole in the block, and was repaired with 77 electrodes. Engine block welding has never been easier!

Cast Iron Drivers Welding

This welding video will be related to a cast iron engine block repair and a cast iron exhaust manifold repair. Both will have a specific process that will be best suited for the.

Welding a cast Iron engine Block

While it is possible to weld an engine block crack, it is not always recommended, since repair jobs on engine blocks may not always hold up to the forces produced within the engine. However, there may be cases when the cracks are minor, enabling you to weld carefully to avoid complete engine block replacement.

6.1 Hemi Cast Iron Engine Block

#1 how to weld cast engine block 11-26-2008, 06:18 AM what is the best rods and way to weld a crack in water jacket on a cast block of old tractor? Tags: None abprt Member Join Date: Nov 2007 Posts: 37 #2 11-26-2008, 07:17 AM Repairing a crack in motor block It would be best if you checked out using the pinning tech. to repair that motor block.